Kundan Mal

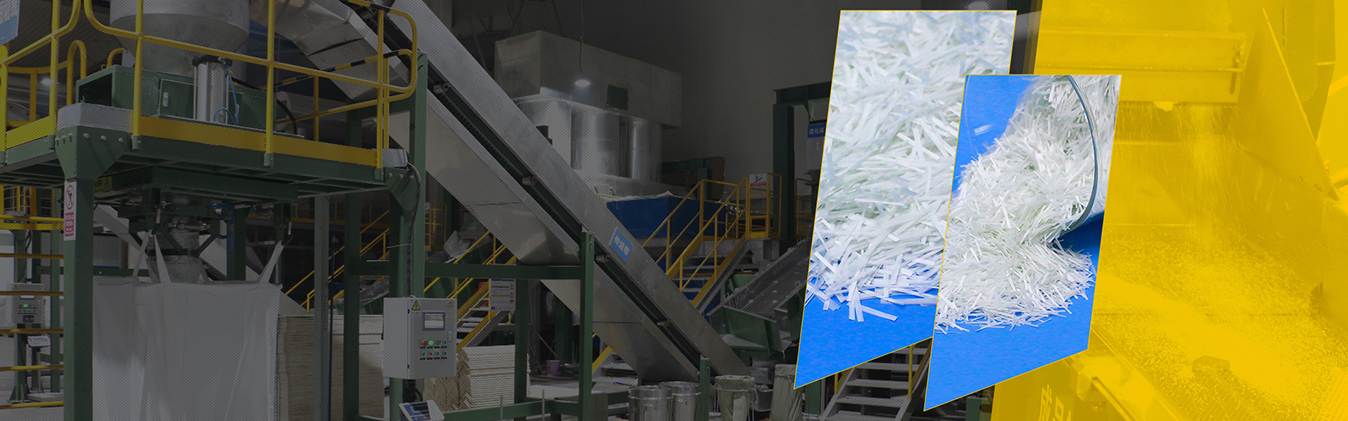

“We use YuNiu glass fiber chopped strands extensively for BMCs in our manufacturing process. Chopped strands are easily incorporated into our BMC formulations and have significantly improved the mechanical properties of our composite structures. Its performance and reliability have given us Very impressed with YuNiu chopped strands."