Ezhova Svetlana

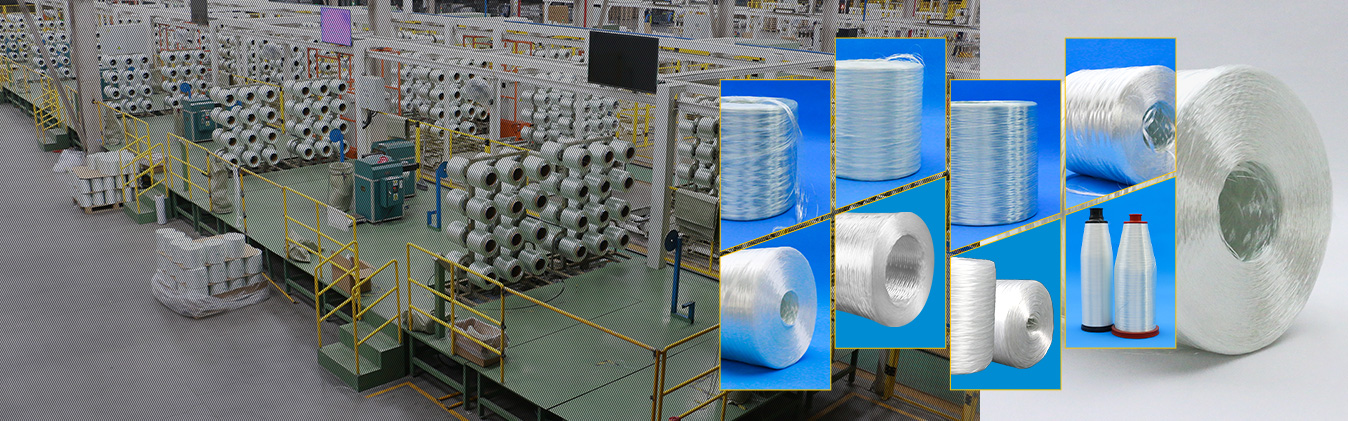

"I had the opportunity to visit your factory in 2022, and I was deeply impressed by your modernization level and advanced production equipment and technology. Compared with other suppliers, your products are very stable and reliable. I Confident in their performance and highly recommend them."