Mehmet Kutluay

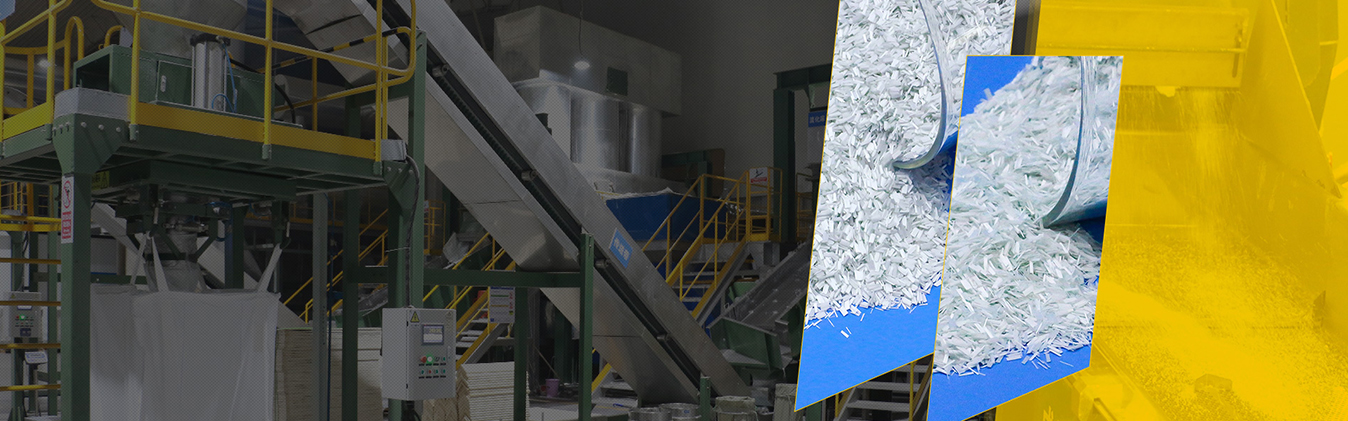

We were having trouble choosing the right fiber length and content. Yuniu Glass Fiber Chopped Shreds Division provides us with various guidance methods, and through sufficient experiments and analysis, we have determined the most suitable method for a specific application. Optimal fiber length and content for enhanced performance and compliance with industry requirements.