Daisy Mimi

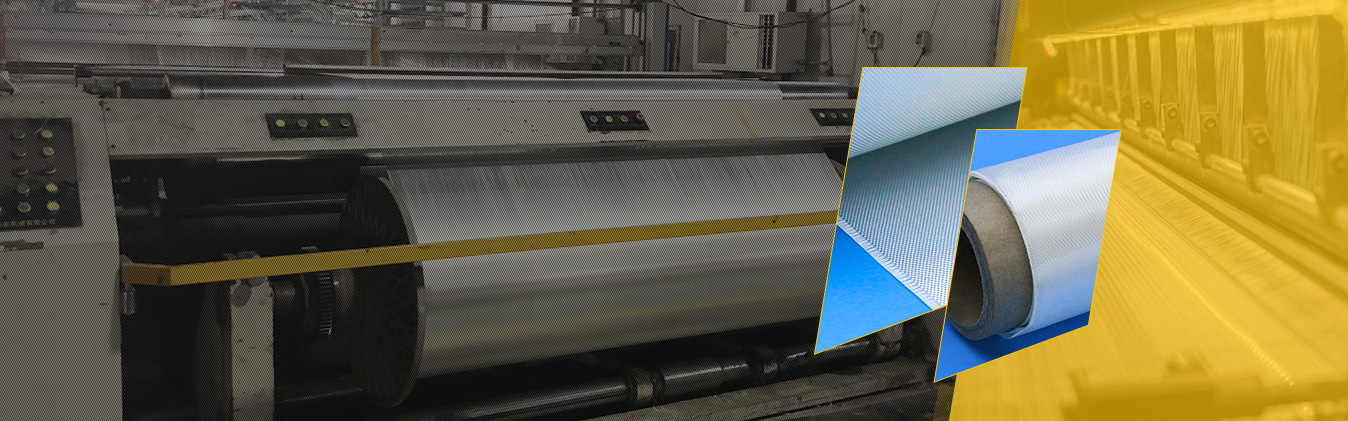

"We use YuNiu Fiberglass plain weave extensively in the production of high-strength composite structures. Their fiberglass woven roving is easy to handle and compatible with our resin system making it ideal for our manufacturing process. I am very impressed with the performance and performance of their products. very satisfied with the reliability"